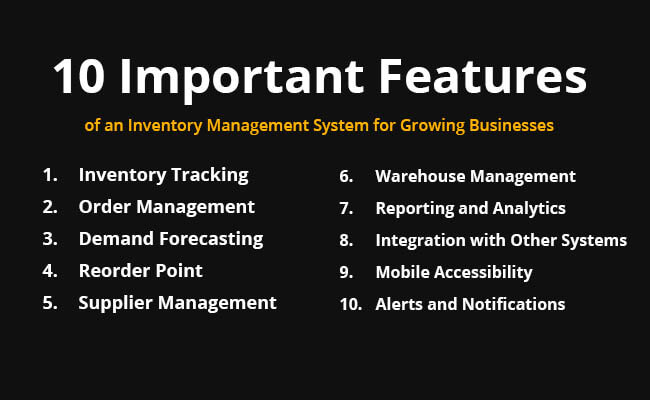

Inventory management plays a critical role in the success of any business. Whether it’s a small retail store or a large manufacturing company, efficient inventory management ensures optimal stock levels, minimizes costs, and enhances customer satisfaction. An inventory management system for growing businesses encompasses various features that enable businesses to efficiently track, control, and manage their inventory.

In this blog, we will delve into the world of inventory management systems, exploring the top 10 features to look for.

1. Inventory Tracking

This is the process of monitoring and managing a company’s stock of goods and materials. It involves keeping track of inventory levels, movements, and changes within a business or organization. The primary goal of inventory tracking is to ensure that a company has the right amount of inventory available at the right time to meet customer demands while minimizing carrying costs and avoiding stockouts or overstock situations. Inventory tracking typically involves several key elements:

- Inventory Count: Regularly counting and recording the quantity of each item in stock to have an accurate representation of what is available. Regular and frequent counting (cycle counting) is highly recommended as a way of not only keeping accurate inventory it allows to better identify business process errors that cause inventory inaccuracies (in the wrong place, Bills of Materials are wrong, shrinkage by manufacturing yield or even theft)

- Stock Movement: Tracking the inflow and outflow of inventory items, including purchases, sales, returns, reworks and transfers between internal legal entities/companies, locations, bins or departments.

- Reorder Point: Establishing a minimum inventory level that, when reached, triggers the need to reorder more items to avoid running out of stock.

- Safety Stock: Keeping a buffer of extra inventory to account for unexpected demand fluctuations or supply chain disruptions.

- Barcode/RFID Scanning: Using technology like barcodes or RFID tags to eliminate manual errors, automate and streamline the tracking process.

- Inventory Software: Utilizing specialized inventory management software, preferably in real-time using mobile devices, to organize and analyze inventory data, streamline operations, and make informed decisions.

2. Order Management

An inventory management system helps streamline the order processing workflow. It enables businesses to receive and process customer orders, allocate inventory, track order status, and generate packing slips and invoices. The order management process involves several stages, each of which plays a significant role in ensuring a smooth and efficient customer experience:

- Order Placement: This stage begins when a customer places an order for products or services. This can by such means as; phone, mail, fax (yes fax is still being used), EDI and eCom

- Order Processing: After receiving the order, the order management system checks the inventory to ensure the requested items are in stock.

- Order Fulfillment: This stage involves picking the items from the warehouse or designated storage locations, packing them securely, and preparing them for shipment or delivery.

- Shipping and Delivery: Once the order is packed and ready, it is shipped or delivered to the customer’s specified address. Shipping options may include standard delivery, express shipping, or other methods, depending on the customer’s preferences and the company’s logistics capabilities.

- Order Tracking: Throughout the process, customers may be provided with tracking information to monitor the status of their orders and receive real-time updates on their shipment’s location and estimated delivery time.

- Order Confirmation and Invoicing: After the order is fulfilled, the customer receives an order confirmation, which can also serve as a receipt.

- Order Returns and Customer Support: If customers are dissatisfied with their orders or receive defective or incorrect items, they may request returns or exchanges. A good inventory management solution allows for return and the tracking there of including RMA with a tracking number that can be verified when the returned good hit your receiving door and a process for handling those goods inside your building including the financial accounting.

3. Demand Forecasting

Demand forecasting involves analyzing historical sales data, market trends, customer behavior, economic factors, planned marketing campaigns, and other relevant information to make predictions about future demand. The primary objectives of demand forecasting in inventory management are:

- Optimizing Inventory Levels: By accurately forecasting demand, businesses can maintain the right amount of inventory at any given time. This helps prevent stockouts that lead to lost sales opportunities and excess inventory that ties up capital and increases storage costs.

- Efficient Production and Procurement: With accurate demand forecasts, companies can plan their production and procurement processes more efficiently. They can schedule manufacturing or purchasing activities to align with anticipated demand, reducing lead times and improving overall supply chain efficiency.

- Cost Reduction: Efficient demand forecasting can lead to cost savings in various areas. By avoiding overstock situations, businesses can reduce carrying costs, minimize the risk of inventory obsolescence, and avoid markdowns to clear excess inventory.

4. Reorder Point and Safety Stock Calculation

The system calculates reorder points and safety stock levels based on demand patterns, lead times, and desired service levels. This ensures timely replenishment and safeguards against stockouts during the procurement process.

- Reorder Point (ROP): The reorder point is the inventory level at which a new order should be placed to replenish stock before it runs out, taking into account the lead time required for order processing and delivery. It ensures that there is sufficient stock available to cover demand during the lead time.

- Safety Stock: Safety stock is a buffer quantity of inventory kept on hand to account for demand variability and uncertainties in the supply chain. It helps protect against unexpected fluctuations in customer demand or delays in procurement, production, or delivery. The level of safety stock depends on factors such as demand variability, lead time variability, desired service level, and the cost of stockouts. A higher safety stock level provides a higher service level but increases carrying costs, while a lower safety stock level reduces carrying costs but increases the risk of stockouts.

5. Supplier Management

In an inventory management system, supplier management refers to the process of overseeing and coordinating the relationships with suppliers or vendors who provide the goods and materials required to maintain adequate inventory levels. It involves various tasks and activities aimed at ensuring a seamless and efficient supply of products from suppliers to the company’s inventory. Effective supplier management is crucial for optimizing inventory levels, minimizing lead times, reducing costs, and improving overall supply chain performance. Here are some key aspects of supplier management in an inventory management system:

- Supplier Selection and Qualification: The first step in supplier management is identifying and selecting suitable suppliers. This process involves evaluating potential vendors based on criteria such as product quality, reliability, pricing, capacity, financial stability, organizational flexibility/adaptability to accommodate last minute changes that invariably occur and their ability to meet delivery schedules.

- Negotiation and Contracting: Once suppliers are chosen, the company negotiates terms and conditions, pricing, payment terms, delivery schedules, and other contractual agreements. Clear and mutually beneficial contracts are essential to establishing a strong working relationship.

- Order Placement and Processing: The inventory management system facilitates the process of placing orders with suppliers, tracking their status, and managing the flow of goods from the supplier to the company’s inventory.

- Lead Time Management: Monitoring, managing and adjusting for accurate lead times is crucial for efficient inventory management. Suppliers are expected to deliver goods within agreed-upon lead times, and any delays can affect inventory levels and customer service.

- Quality Control and Assurance: Ensuring the quality of goods received from suppliers is essential to avoid issues such as defective products or returns. Supplier management involves implementing quality control measures and collaborating with suppliers to address quality concerns promptly. As organizations move from Quality Control to Quality Assurance you will find yourself getting involved in your suppliers processes to ensure that those processes are designed and executed to support the required quality level.

6. Warehouse Management

This feature focuses on optimizing warehouse operations, including inventory receipt, put-away, picking, packing, and shipping. It may include functionalities like:

- Bin/location management

- Wave picking

- Integration with shipping carriers

- Multiple inventory condition expiry date, expiry date looking forward, FIFO, lot/batch/serial assigned by customer

- Attributes: temperature, humidity, secured location

7. Reporting and Analytics

Inventory management systems generate comprehensive reports and provide analytics to gain insights into inventory performance, demand trends, and inventory holding costs. These insights aid decision-making processes, identify areas for improvement and optimize inventory management strategies. Here’s an overview of reporting and analytics in an inventory management system:

- Real-Time Inventory Visibility: Reporting capabilities in the system allow users to access real-time information about the current inventory levels, item availability, and stock movements. This visibility helps ensure accurate stock counts and aids in managing replenishment and reordering processes.

- Inventory Performance Metrics: Inventory management systems generate various performance metrics and KPIs, such as inventory turnover, stockout rate, fill rate, carrying costs, and obsolete inventory. These metrics provide a clear understanding of inventory health and efficiency.

- Stock Aging Analysis: Inventory aging reports help identify slow-moving or obsolete items. This information enables businesses to take proactive measures such as markdowns, promotions, or return to suppliers to manage aging inventory effectively.

- Data Visualization: Data visualization tools such as charts, graphs, and dashboards help present inventory-related data in a visually appealing and easy-to-understand manner. This allows users to grasp key insights quickly and make informed decisions.

8. Integration with Other Systems

Inventory management systems often integrate with other business systems, such as point of sale (POS), enterprise resource planning (ERP), or accounting software. Integration ensures seamless data flow, eliminates duplicate data entry, and synchronizes information across different departments. Integrating your inventory management system with an Enterprise Resource Planning (ERP) system offers numerous advantages and is highly beneficial for businesses. The integration enhances the efficiency and accuracy of various processes and provides a holistic view of the organization’s end-to-end operations. Here are some of the key importance of integrating your inventory management system with an ERP:

- Real-Time Data Synchronization: Integration ensures that inventory data is automatically updated in real-time across all relevant modules within the ERP system. This eliminates the need for manual data entry and reduces the risk of errors and discrepancies in inventory records.

- Streamlined Workflows: Integrating inventory management with an ERP allows for seamless and streamlined workflows. It enables a cohesive flow of information between departments, such as sales, procurement, finance, and production, improving collaboration and reducing delays.

- Enhanced Visibility and Control: ERP integration provides a comprehensive view of inventory levels, demand, and stock movements. This visibility enables better decision-making, improved demand forecasting, and more effective inventory planning.

9. Mobile Accessibility

Many inventory management systems offer mobile applications or web-based interfaces, allowing users to access and update inventory information from anywhere using smartphones or tablets. This feature is particularly useful for on-the-go inventory management, stocktaking, or order processing. Mobile access is important in inventory management for several reasons, as it brings significant benefits and efficiency to the overall inventory control process. Here are some key reasons why mobile access is crucial in modern inventory management:

- Real-Time Data and Updates: With mobile access to inventory management systems, employees can access real-time data about inventory levels, stock movements, and order statuses on the go. This information is vital for making informed decisions and responding quickly to changing inventory demands.

- Remote Inventory Management: Mobile access allows inventory managers and warehouse personnel to monitor and manage inventory from anywhere, enabling them to stay connected even when they are away from the main office or warehouse.

- Increased Productivity: Mobile inventory management applications facilitate faster and more efficient workflows. Employees can perform inventory-related tasks, such as stock counts, order processing, and receiving, directly on their mobile devices, reducing the need for manual paperwork and data entry.

- Barcode Scanning and RFID Integration: Mobile devices often come equipped with built-in cameras that can function as barcode scanners. This integration enables employees to scan barcodes or RFID tags for accurate and quick inventory tracking and updates.

- Faster Issue Resolution: If an inventory discrepancy or issue arises, mobile access enables employees to investigate and resolve the problem on the spot, minimizing the impact on operations.

9. Mobile Accessibility

Many inventory management systems offer mobile applications or web-based interfaces, allowing users to access and update inventory information from anywhere using smartphones or tablets. This feature is particularly useful for on-the-go inventory management, stocktaking, or order processing. Mobile access is important in inventory management for several reasons, as it brings significant benefits and efficiency to the overall inventory control process. Here are some key reasons why mobile access is crucial in modern inventory management:

- Real-Time Data and Updates: With mobile access to inventory management systems, employees can access real-time data about inventory levels, stock movements, and order statuses on the go. This information is vital for making informed decisions and responding quickly to changing inventory demands.

- Remote Inventory Management: Mobile access allows inventory managers and warehouse personnel to monitor and manage inventory from anywhere, enabling them to stay connected even when they are away from the main office or warehouse.

- Increased Productivity: Mobile inventory management applications facilitate faster and more efficient workflows. Employees can perform inventory-related tasks, such as stock counts, order processing, and receiving, directly on their mobile devices, reducing the need for manual paperwork and data entry.

- Barcode Scanning and RFID Integration: Mobile devices often come equipped with built-in cameras that can function as barcode scanners. This integration enables employees to scan barcodes or RFID tags for accurate and quick inventory tracking and updates.

- Faster Issue Resolution: If an inventory discrepancy or issue arises, mobile access enables employees to investigate and resolve the problem on the spot, minimizing the impact on operations.

10. Alerts and Notification

The system can send automated alerts and notifications to users based on predefined conditions. These notifications may include low stock alerts, reorder reminders, or exceptions like stock discrepancies or expired items. These alerts help businesses stay on top of inventory-related activities, potential issues, and critical events. Here are some common types of alerts and notifications in an inventory management system:

- Low Stock Alerts: When the stock level of a particular item falls below a predefined threshold, the system generates a low stock alert. This alert prompts inventory managers to initiate reordering processes to prevent stockouts. Expiry or

- Shelf Life Alerts: For perishable or time-sensitive items, the system can send alerts when products are nearing their expiration date or shelf life. This ensures that such items are prioritized for sale or removed from inventory in a timely manner.

- Overstock Alerts: Conversely, the system can notify inventory managers when stock levels exceed a certain limit. Overstock alerts help prevent excessive inventory that ties up capital and increases carrying costs.

- Reorder Point Alerts: Based on demand forecasting and lead time, the system can generate alerts to indicate the appropriate time to place new orders. This ensures that the reorder point is reached before running out of stock.

- Supplier Performance Alerts: When a supplier’s performance falls below specified benchmarks, such as delayed deliveries or frequent quality issues, the system can trigger alerts. This helps inventory managers take corrective actions or consider alternative suppliers.

- Backorder Alerts: If an item is out of stock but still in demand, the system can alert customers and the sales team about the backorder status, allowing for better customer communication.

- Shipping and Delivery Alerts: Alerts can be sent when orders are shipped, along with tracking information. This keeps customers informed about the status of their orders and enhances transparency in the delivery process.

Conclusion

Implementing a robust inventory management system is crucial for businesses seeking to optimize their operations and gain a competitive edge. With streamlined inventory processes, accurate demand forecasting, and real-time data insights, companies can reduce costs, improve customer service, and make data-driven decisions. By embracing the power of inventory management systems, businesses can effectively manage their inventory, enhance their supply chain, and position themselves for long-term success in today’s fast pace, technology-driven landscape. If you are looking for a robust system that will handle your inventory and warehouse, schedule a free demo with us.