BWISE Manufacturing Solution

Unlock the power of efficient manufacturing with our top tier ERP Manufacturing Module. Whether you’re in discrete, process, or mixed-mode manufacturing, our solution is tailored to optimize your production processes, reduce costs, and boost productivity.

Our BWISE MFG manufacturing modules are meticulously crafted to meet the diverse needs of small to med-size manufacturing environments. With special emphasis on:

- Make-to-Order (MTO)

- Make to Stock (MTS)

- Engineer to Order (ETO)

- Process Manufacturing

- Discrete Manufacturing

- Job Shop

- Repetitive Manufacturing

- Sequencing

Learn from our experts how you can drive more business with SAP Business One – ERP Software

ERP Solution for Manufacturing

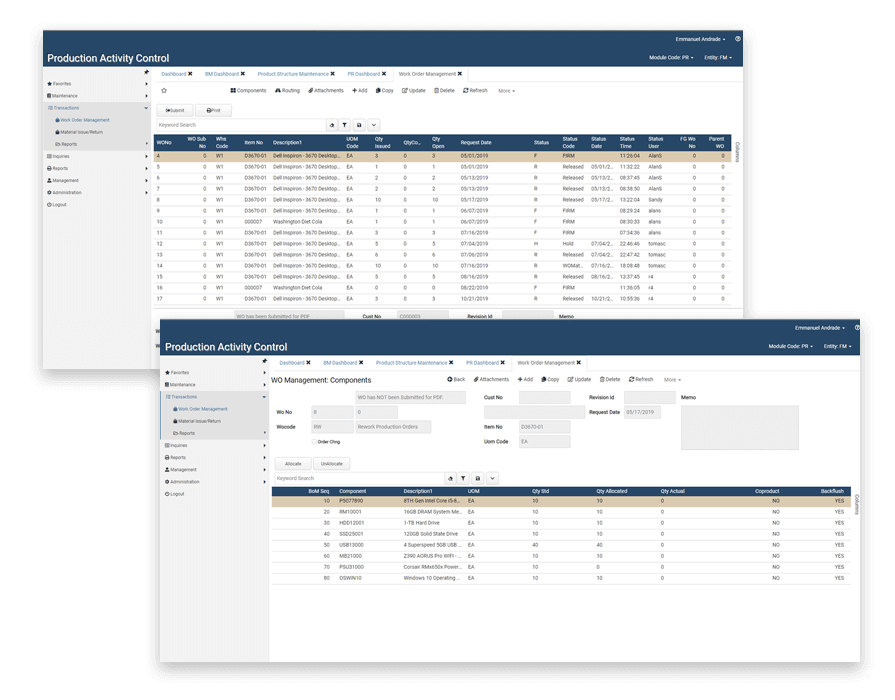

Production Planning & Scheduling:

Seamlessly plan and schedule your manufacturing processes to meet demand efficiently. Our production planning and Scheduling module helps you optimize resource utilization and minimize lead times.

- Dispatch list by operation

- Production work orders

- WIP tracking & costing

- Component Inventory control

- Automatic inventory/lot allocation if desired

- Produces labor reports by employee, work order, operation, and work center

- Variance reporting

- Backflushing & kanban supported

- Advanced Planning and Scheduling with a Graphical Planner Board with bottle-neck identification (including drag and drop capability)

- Smart-forecast for Sales Planning

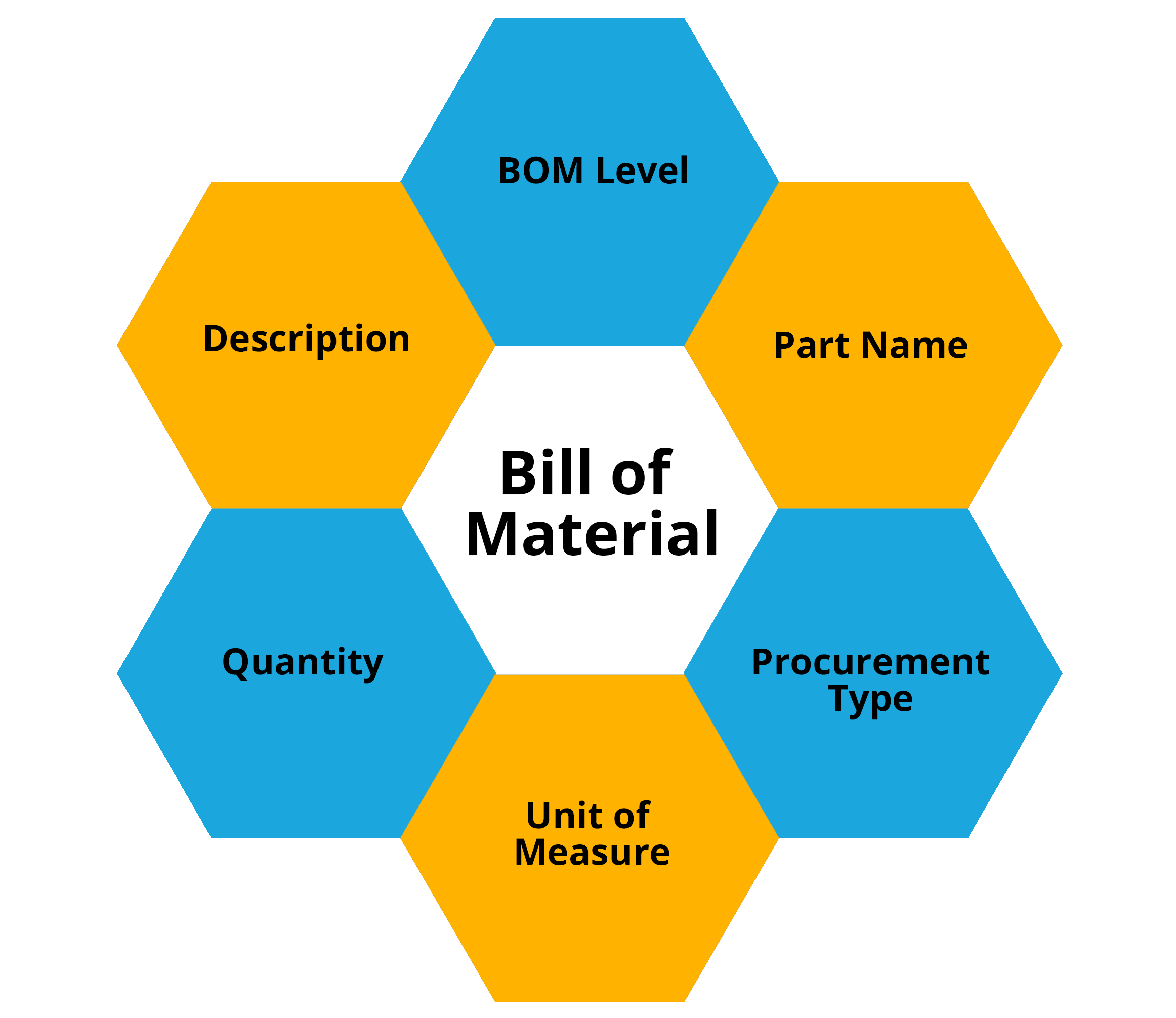

Bill of Materials (BOM) Management:

Maintain accurate and up-to-date BOMs for all your products. Manage multi-level BOMs efficiently and track changes seamlessly. Automatic calculation with cost entry

- Costed bill of materials

- Automatic calculation with cost entry

- Indented BoM’s with unlimited levels

- Complete sub-assembly support

- Phantom and Stockable Subassembly support

- Source compare

- Cost roll-up

- User defined & easy data entry

- Outside processing tracked

Materials Requirement Planning (MRP):

Our MRP helps ensure that the right materials are available at the right time in the right quantities to support production activities efficiently. MRP calculates the materials needed based on production schedules, sales forecasts, and existing inventory levels.

- Complete Integration to all other modules

- User-defined planning periods (unlimited)

- Pegs requirements to next or top-level assembly

- Supports phantoms

- Exception reporting

- Bar Code Compatible

- Demand generated from orders & forecasts

- User infinite backward scheduling logic

- Infinite Planning

Capacity Management:

Our Capacity Management component focuses on optimizing and maximizing the utilization of resources within manufacturing operations. It involves work centers and machine control to meet production demands efficiently. By leveraging our capacity management tools and real-time data, organizations can enhance their capacity planning capabilities and achieve sustainable growth.

- Maximize Manufacturing Efficiencies

- Full utilization of all resources

- Availability Check (ATP) without running MRP

- What if capabilities

- Work Center Control

- Machine Control

- Resource Planning

Core Modules

Production Planning & Scheduling

Bill of Materials (BOM) Management

Materials Requirement Planning (MRP)

Capacity Management

Unlock the Full Potential of your Business!

Don't miss out on our exclusive content. Our brochure and whitepaper are packed with expert analysis, case studies, and practical tips that can help you understand the latest trends and strategies in logistics and ERP. Don't miss out on this opportunity to expand your knowledge and elevate your expertise.

ADDRESS

International Corporate Headquarters

5000 E. Spring Street, Suite 415

Long Beach, CA 90815