When it comes to the manufacturing industry, every second counts. Efficient operations and streamlined processes are vital for success. This is where ERP systems for manufacturing come into play. These robust software solutions are specifically designed to optimize efficiency and drive productivity in manufacturing businesses.

Manufacturing ERP software offers a wide range of benefits that help companies stay ahead of the competition. By integrating various departments and processes into a centralized system, ERP software provides real-time visibility, improved communication, and enhanced decision-making capabilities. With accurate data and analytics at their fingertips, manufacturers can make informed decisions that lead to optimized efficiency and increased profitability.

Key features to look for in manufacturing ERP software include inventory management, production planning, order tracking, supply chain management, and financial integration. These features work together to ensure smooth operations, minimize downtime, and reduce costs.

Key Takeaways:

- ERP systems for manufacturing optimize efficiency and streamline operations.

- Manufacturing ERP software provides real-time visibility and improved decision-making capabilities.

- Key features of manufacturing ERP software include inventory management, production planning, order tracking, supply chain management, and financial integration.

Best ERP Systems for Manufacturing

In the manufacturing industry, choosing the right ERP system is crucial for optimizing efficiency and streamlining operations. To help you make an informed decision, we have compiled a list of the best ERP systems available. These top-rated solutions offer a range of features and benefits, designed specifically to address the unique needs of the manufacturing sector.

SAP S/4HANA

SAP S/4HANA is a leading ERP software that provides comprehensive functionality for manufacturing businesses. With its advanced analytics and real-time insights, SAP S/4HANA enables manufacturers to optimize production planning, manage supply chain operations, and improve inventory management. Its cloud-based platform ensures scalability and flexibility, making it an ideal choice for manufacturers of all sizes.

Oracle NetSuite

Oracle NetSuite is a cloud-based ERP system that offers a range of modules tailored to meet the unique requirements of manufacturing businesses. From procurement and inventory management to order fulfillment and production planning, Oracle NetSuite provides end-to-end visibility and control over manufacturing operations. Its robust reporting and analytics capabilities enable manufacturers to make data-driven decisions and drive business growth.

Microsoft Dynamics 365 for Finance and Operations

Manufacturing organizations can benefit from a comprehensive ERP solution like Microsoft Dynamics 365 for Finance and Operations, which is tailored to their unique requirements. Microsoft Dynamics 365’s integrated modules for supply chain management, production control, and quality management enable manufacturers to increase customer satisfaction, streamline operations, and collaborate across teams more effectively. Productivity and efficiency are further increased by its smooth connection with other Microsoft products, such Office 365.

These are but a handful of the top ERP programs for the industrial sector. Every system has unique features and strengths that meet various manufacturing requirements. The greatest ERP system can help you maximize manufacturing operations and propel business success if you properly consider its features and match it with your unique needs.

ERP Solutions for Manufacturing Industry

In the fast-paced and highly competitive manufacturing industry, efficient resource planning is crucial for success. That is where ERP solutions come in. ERP, or Enterprise Resource Planning, systems provide comprehensive tools and features specifically designed to address the unique challenges faced by manufacturers. Let us explore how these solutions can revolutionize your manufacturing operations.

Manufacturing Resource Planning Systems

Manufacturing resource planning systems are the backbone of ERP solutions for the manufacturing industry. These systems enable manufacturers to effectively manage their resources, including materials, equipment, and labor, to ensure smooth production processes and optimize efficiency.

With manufacturing resource planning systems, you can:

- Track and manage inventory levels in real-time to avoid stock shortages or excesses

- Streamline production scheduling and optimize capacity utilization

- Monitor equipment downtime and proactively schedule maintenance

- Allocate labor resources efficiently and ensure adequate staffing

ERP Implementation in Manufacturing Industry

Implementing an ERP system in the manufacturing industry can be a significant change. By integrating all business functions and processes into a single unified platform, you can eliminate data silos, improve communication, and enhance collaboration across departments.

Benefits of ERP implementation in the manufacturing industry include:

- Real-time visibility into production processes, enabling quick decision-making and problem-solving

- Improved accuracy and reliability of data, reducing errors and rework

- Enhanced supply chain management, optimizing procurement and reducing lead times

- Efficient financial management, including cost control and accurate forecasting

With ERP solutions tailored to the manufacturing industry, you can gain a competitive edge by increasing productivity, reducing costs, and delivering high-quality products on time.

Conclusion

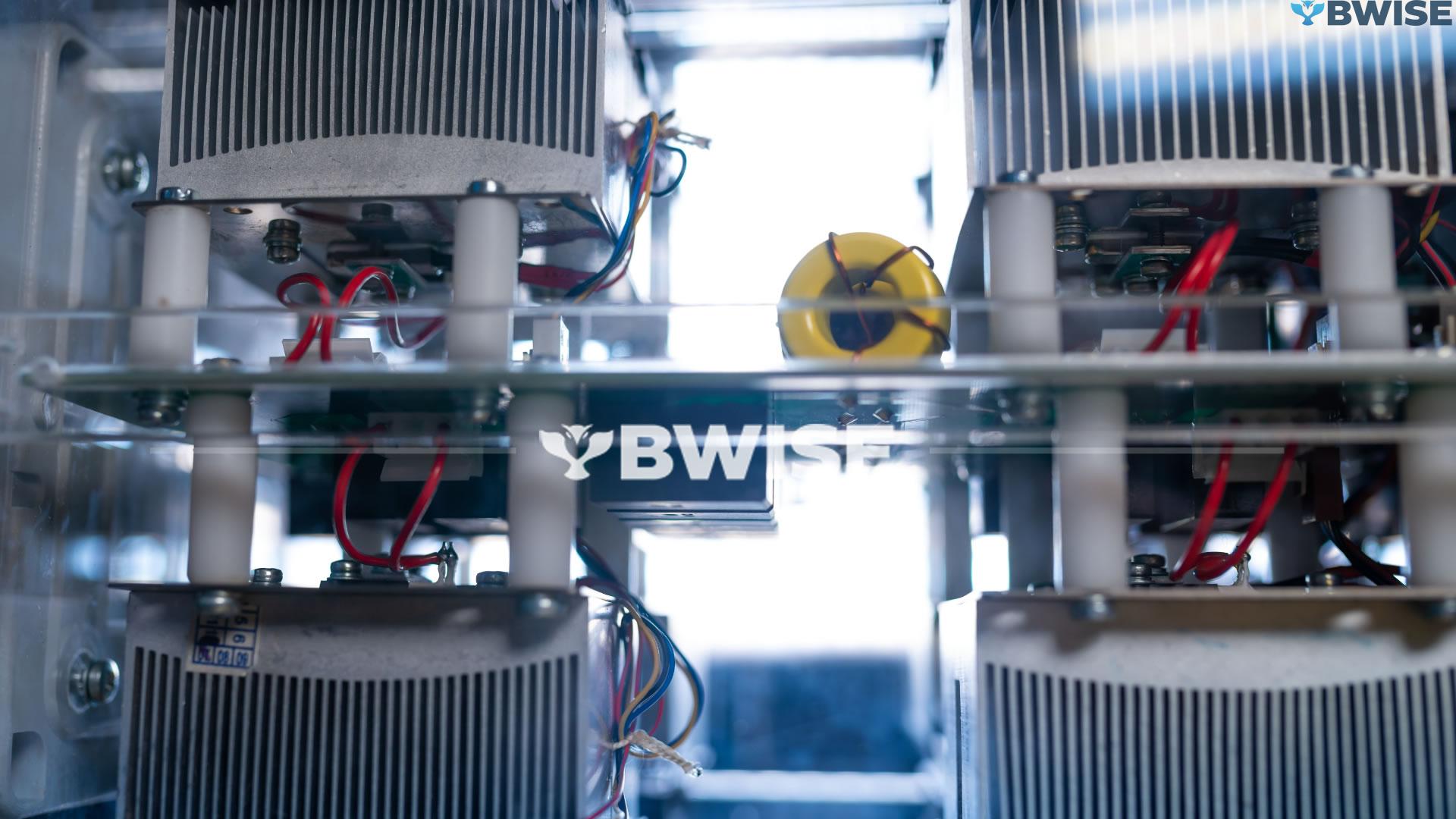

In conclusion, the implementation of ERP systems, like BWISE in the manufacturing industry, brings numerous benefits, and contributes to overall operational efficiency. By adopting the right ERP software, manufacturers can optimize their processes, improve resource planning, and drive industry growth.

By improving supply chain integration, production scheduling, and inventory management, manufacturers may optimize their operations with an ERP system in place. Businesses are able to make well-informed decisions and promptly address market demands because to these systems’ real-time data visibility and analytics.

In addition, ERP systems facilitate smooth coordination and minimize bottlenecks by improving departmental collaboration and communication. Together with order tracking, post-sale assistance, and customer data management, they offer a centralized platform that enhances customer happiness and retention.

The correct ERP software selection for manufacturing is essential since it should support the unique requirements and objectives of the company. Before making a choice, manufacturers should consider aspects such as vendor dependability, industry-specific features, scalability, and integration options. Need more information about our ERP software? You can request a demo here. Remember B1 BWISE!