Before diving deep into the functional requirements for choosing a new warehouse management system, let’s ask the most important questions. Are you ready for a WMS, or do you want to replace your current one? Those are the first questions that sometimes people in the logistics field forget to ask themselves. Getting a new WMS can be a complex process that involves many people in your organization. It requires a firm and dedicated set of people resources to be successful. Implementation frequently sometimes fails due to poor planning.

With a limited budget, one has to pick and plan carefully not only for the next few years but also for the far into the future. As much as you looking to pick the best software it is equally imperative to choose the right vendor that suits the needs and culture of your business.

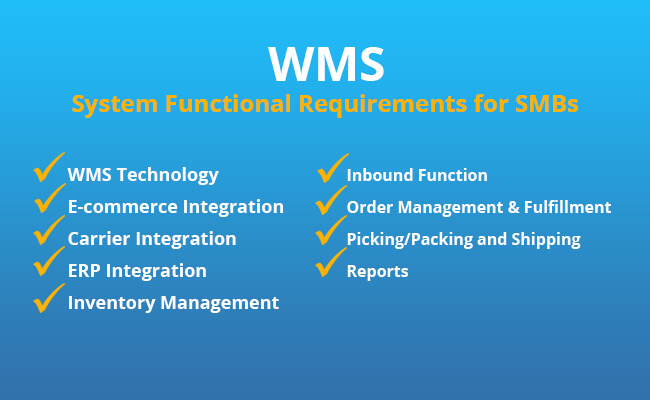

We have prepared this article in order to give those new in the logistics field a foundation to build on in their quest to take their warehouse and logistics operations to the next level. In this article, we will cover:

- WMS Technology

- Broad Questions

- Specific Technology

- Cloud Based WMS

- Locally Hosted WMS

- E-commerce Integration

- Carrier Integration

- ERP Integration

- Inventory Management

- Inbound Function

- Order Management and Fulfillment

- Picking/Packing and Shipping

- Reporting

1. WMS Technology

Choosing the right Warehouse Management System (WMS) technology is crucial for several reasons, as it directly impacts the efficiency, productivity, and overall success of warehouse operations. Here are some key questions you need to ask the WMS provider:

-

- Broad Questions:

- How does it Improve Operational Efficiency?

- An effective WMS streamlines warehouse processes, automates tasks, and optimizes workflows. By choosing the right technology, businesses can improve order fulfillment speed, reduce errors, and enhance overall operational efficiency.

- Will it Improve Inventory Accuracy?

- Accurate inventory management is critical to meeting customer demands and avoiding stockouts or overstock situations. The right WMS technology ensures real-time tracking, precise inventory counts, and visibility into stock levels, minimizing the risk of costly inventory discrepancies.

- Can it Optimize my Warehouse Layout?

- A WMS system can help optimize warehouse layout and bin locations. It assists in organizing items based on demand and storage requirements, reducing unnecessary movements and improving overall warehouse productivity.

- Does it Increase my Labor Productivity?

- WMS systems should optimize labor utilization by providing task assignments, tracking employee performance, and streamlining workflows. This leads to increased labor productivity and reduced operational costs.

- How does it Improve Operational Efficiency?

- Broad Questions:

-

- Specific Technology:

- Is it a Cloud Based Application or is it deployed on-premise in your facility?

- Web-based Warehouse Management Systems (WMS) and locally hosted WMS (also known as on-premises WMS) are two different deployment options for warehouse management software. Each option has its advantages and disadvantages, and the choice between them depends on the specific needs and preferences of the business. Let’s compare web-based and locally hosted WMS:

- Web-Based WMS – Web-based WMS is accessible through a web browser, allowing users to access the system from anywhere with an internet connection. This makes it ideal for businesses with multiple locations or those that require remote access for employees or third-party partners. Web-based WMS is typically more scalable, as the infrastructure is maintained by the WMS provider. Businesses can easily scale up or down based on their changing needs without worrying about hardware upgrades or server capacity. In web-based WMS the provider system back-ups, fail over environments, handles maintenance, updates, and software upgrades, relieving businesses of the burden of managing IT infrastructure and ensuring the system is up-to-date. Web-based WMS often involves lower upfront costs, as there is no need to invest in dedicated hardware or servers. Instead, businesses pay a subscription fee based on usage, making it a more cost-effective option for some. From an accounting perspective, web-based subscription solutions are treated as an expense

- Locally Hosted WMS (On-Premise) – With locally hosted WMS, businesses have complete control over their data and infrastructure. This can be critical for companies with strict data security, compliance requirements, data back-up and disaster recovery. Locally hosted WMS allows for greater customization and tailoring to specific business needs, as businesses can have direct access to the software’s source code and modify it as required. Some businesses may perceive locally hosted WMS as more secure, as they can implement their own security measures and control access to the system within their own network. While the upfront costs for locally hosted WMS can be higher due to infrastructure investments, over the long term, the total cost of ownership may become comparable or lower than a web-based solution.

- Web-based Warehouse Management Systems (WMS) and locally hosted WMS (also known as on-premises WMS) are two different deployment options for warehouse management software. Each option has its advantages and disadvantages, and the choice between them depends on the specific needs and preferences of the business. Let’s compare web-based and locally hosted WMS:

- Does it support the various devices used to run an efficient and modern warehouse such as:

- Handheld Barcode Scanners

- Mobile Computers and Smartphones

- RFID Readers

- Forklifts and Material Handling Equipment

- Voice Picking Devices

- Pick-to-Light and Put-to-Light Systems

- Printers and Labeling Devices

- Is it a Cloud Based Application or is it deployed on-premise in your facility?

- Specific Technology:

2. E-commerce Integration

E-commerce plays a crucial role in a Warehouse Management System (WMS) due to the growing significance of online retail and the need for seamless integration between order fulfillment and warehouse operations. E-commerce integration ensures that inventory levels in the online store are synced with the WMS inventory. As orders are placed online, the WMS automatically updates inventory levels, avoiding stockouts and overselling. E-commerce integration enables support for multichannel sales, including online marketplaces, third-party websites, and direct online stores. A centralized WMS can handle orders from various sales channels efficiently and in real-time. As your business grows, planning for future sales channels is important. Here are some E-commerce platform that you might consider when it comes to integration:

-

- Amazon

- eBay

- Shopify

- Magento

- Walmart

- Wayfair

- Houzz

- Woocommerce

- BigCommerce

- Jet

- Groupon

- Amazon FBA

- Etsy

3. Carrier Integration

Carrier integration is essential in a Warehouse Management System (WMS) because it enables seamless communication and collaboration with shipping carriers, leading to numerous benefits for the warehouse and the overall supply chain. Your chosen WMS should connect with your preferred carrier/s. A flexible WMS can connect with different carrier services making the decision of changing and adding carriers later on easier. Here is a list of popular carrier services:

-

- Rate Shopping Across Carriers

- UPS Mail Innovations

- International UPS

- Integration USPS

- Endicia Integration

- FedEx Integration

- DHL E-commerce Integration

- DHL Global Integration

- DHL Express Integration

- UPS Mail Innovations

- Fedex Smartpost

- FedEx Commercial Invoice Letterhead and Signature Function

- Fedex One Rate

- Commercial Invoice Customization Support

4. ERP Integration

ERP (Enterprise Resource Planning) and WMS (Warehouse Management System) are two distinct but closely related software systems that play critical roles in managing various aspects of a business’s operations, including inventory and warehouse management. Integrating the WMS with the ERP offers several advantages and is crucial for efficient and streamlined supply chain management. Here are the reasons why a WMS that integrates to your ERP is important:

-

- Seamless Data Flow: Integration between the WMS and ERP enables seamless data flow and real-time updates between both systems. This integration ensures that all relevant data, including inventory levels, order information, and customer data, remains consistent and up-to-date across both platforms.

- Accurate Inventory Management: By integrating the WMS with the ERP, you can maintain accurate and synchronized inventory records. When an item is received or shipped in the warehouse, the information is immediately updated in the ERP, providing accurate inventory levels for other departments like sales, accounting, and procurement.

- Efficient Resource Planning: Integration between the WMS and ERP enables better resource planning and allocation. The ERP can use real-time data from the WMS to optimize inventory levels, warehouse staff, and equipment usage, leading to more efficient warehouse operations.

5. Inventory Management

Inventory management is a fundamental aspect of a Warehouse Management System (WMS) as it plays a central role in optimizing warehouse operations and achieving overall supply chain efficiency. Effective inventory management in a WMS ensures that the right quantity of products is available at the right time. By maintaining optimal stock levels, businesses can meet customer demands, avoid stockouts, and reduce excess inventory, leading to cost savings. A WMS provides real-time visibility into inventory levels and locations. Warehouse staff can quickly access inventory data, facilitating efficient order fulfillment and reducing the time spent searching for products. Here are some essential functions of inventory management you might consider in choosing a WMS:

-

- SKU/UPC Barcode Scanning – A WMS that doesn’t support SKU and UPC barcode scanning is not a WMS. Almost all WMS providers support this basic function nowadays.

- Lot/Batch Tracking – Lot/Batch tracking in a Warehouse Management System (WMS) is a feature that enables the systematic tracking and tracing of products based on specific batch or lot numbers. It is particularly important for industries where products are manufactured, processed, or distributed in batches, such as pharmaceuticals, food and beverage, chemicals, and electronics. Lot tracking allows businesses to maintain strict quality control, ensure product safety, and comply with industry regulations.

- Production Date Tracking – Production date tracking in a Warehouse Management System (WMS) is a specific feature that focuses on monitoring and managing products based on their production or manufacturing dates. This functionality is particularly important for industries dealing with perishable goods, pharmaceuticals, and other products with limited shelf life or expiration dates. Production date tracking allows businesses to prioritize and manage inventory based on the age of the products, ensuring that older items are used or shipped first to minimize waste and maintain product freshness. If you are in the food and beverage industry, this is a must function.

- Serial Number Tracking – Serial number is a feature that allows businesses to uniquely identify and trace individual items in their inventory by assigning a unique serial number to each product. This tracking method is commonly used for high-value items, electronic devices, automotive parts, and other products that require individual identification and traceability throughout their lifecycle.

- Expiry Date Tracking – Expiry date tracking in a Warehouse Management System (WMS) is a critical feature that allows businesses to monitor and manage products with limited shelf life or expiration dates. Expiry date tracking enables businesses to ensure product quality, minimize waste, and comply with industry regulations.

6. Inbound Function

The inbound function is a crucial part of warehouse operations, as it involves the accurate and efficient handling of incoming shipments, ensuring that inventory is properly recorded, inspected, and made available for storage or order fulfillment. Here are inbound functions you may need in a WMS:

-

- Purchase Order – The process begins with the receipt of purchase orders from the company’s suppliers or vendors. These purchase orders detail the products to be delivered, their quantities, and other relevant information.

- Document Attachment – A modern WMS should have the capability to associate and store various types of electronic documents with specific warehouse transactions, orders, or inventory records. These documents could be images, PDFs, spreadsheets, text files, or any other file format that contains relevant information related to warehouse operations.

- ASN Management – ASN (Advanced Shipping Notice) management in a Warehouse Management System (WMS) refers to the process of handling and processing ASN documents received from suppliers or vendors before the actual physical arrival of the goods at the warehouse. An ASN is an electronic notification sent by the supplier to the buyer, providing detailed information about the upcoming shipment. Effective ASN management is crucial for efficient inbound logistics and smooth inventory-receiving processes.

- Pallet/LP Receiving – Pallet/LP (License Plate) receiving is a warehouse process that involves the receipt and handling of incoming goods on pallets or with license plates. License plates are unique identifiers assigned to groups of items on a pallet or in a container. This process is commonly used in modern warehouses to streamline the receiving and tracking of large quantities of products efficiently.

7. Order Management and Fulfillment

Order management in a Warehouse Management System (WMS) involves the processes and functionalities that handle the entire lifecycle of customer orders within the warehouse. It is a critical aspect of warehouse operations as it ensures efficient order processing, accurate order fulfillment, and seamless coordination between various departments. Here is a list of order management functions that is critical to a modern warehouse:

-

- Auto order download from online channels – A modern feature of Warehouse Management Systems (WMS) automates the process of receiving and importing customer orders from various online sales channels directly into the WMS. The WMS is integrated with various online sales channels, such as Amazon, eBay, Shopify, WooCommerce, and other popular e-commerce platforms. This integration allows the WMS to communicate and exchange data with these channels seamlessly.

- Manual Order Entry – Manual order entry is a process in which customer orders are entered into a system manually rather than being automatically imported or downloaded from other sources. This method is often used when orders are received through channels that do not have direct integration with the system, such as phone orders, fax orders, or orders received via email.

- Back Order Management – A backorder occurs when a customer places an order for a product, but the item is currently out of stock or unavailable for immediate shipment. Instead of canceling the order, the business records it as a backorder and fulfills it as soon as the product becomes available. Effective backorder management ensures customer satisfaction, maintains inventory accuracy, and optimizes order processing.

- FIFO/FEFO Management – FIFO (First-In-First-Out) and FEFO (First-Expired-First-Out) are inventory management methods used to ensure the proper rotation and usage of goods in a warehouse or distribution center. FIFO (First-In-First-Out) and FEFO (First-Expired-First-Out) are inventory management methods used to ensure the proper rotation and usage of goods in a warehouse or distribution center.

- FIFO is a method where the first items received into inventory are the first ones to be used or sold. The older stock is consumed or sold before newer stock. The idea behind FIFO is to prevent stock from becoming obsolete or reaching its expiration date, especially for products with a limited shelf life.

- FEFO is a more specific application of FIFO, primarily used for managing products with strict expiration dates or shelf life limits. In a FEFO system, the inventory is managed based on the product’s expiration date, and the items that will expire first are used or sold before those with later expiration dates.

8. Picking/Packing and Shipping

Pick, pack, and shipping is a critical process in warehouse management and order fulfillment. It involves the sequential steps of picking items from inventory, packing them into shipments, and arranging their shipping to customers. Listed below are some important function you might need in your WMS

-

- Batch Picking – Batch picking, also known as multi-order picking or cluster picking, is a warehouse order picking strategy designed to increase picking efficiency and productivity. It involves selecting and picking multiple customer orders simultaneously in a single pass through the warehouse. Batch picking is especially beneficial when dealing with a high volume of orders with similar or overlapping items, and it helps reduce travel time and improve order fulfillment speed.

- Zone Picking – The warehouse is divided into distinct zones based on product categories, storage locations, or other logical criteria. Each zone is typically assigned to specific pickers or teams. This approach allows multiple pickers to work simultaneously in different zones, picking items for multiple orders concurrently.

- Multiple Carrier Label Printing – Businesses can manage shipping labels for multiple carriers from a single platform, eliminating the need for separate systems or interfaces for each carrier. By working with multiple carriers, you can choose the most cost-effective or fastest shipping options for each order, providing flexibility to meet customer preferences.

9. Reporting

A good reporting function is an essential warehouse tool that provides valuable insights and analytics about warehouse operations, inventory management, order processing, and overall business performance.

-

- Location-Based Report – A location-based inventory report is a specific type of report generated by a Warehouse Management System (WMS) that provides detailed information about the inventory levels and status of items at different storage locations within the warehouse. The report may include data on the utilization of storage space within the warehouse, highlighting areas where space is either under-utilized or over-utilized

- Shipment History Report – Shipment history is an essential component of a Warehouse Management System (WMS) or shipping software, as it helps businesses track the movement of goods, monitor order fulfillment performance, and provide valuable data for analysis and decision-making. It provides a comprehensive overview of the shipping activities, including details about the shipped orders, shipping carriers used, shipment dates, delivery status, and any associated tracking information. Shipment history details may include the following:

- Order Number: The unique identifier for each shipped order.

- Shipment Date: The date when the shipment was processed or dispatched.

- Customer Information: The name, shipping address, and contact details of the recipient/customer

- Shipment Status: The current status of the shipment, such as shipped, in transit, delivered, or returned.

- Tracking Number: The unique identifier assigned by the shipping carrier to track the shipment’s progress.

-

- Receiving History Report – A record of all past receiving activities in a warehouse or business. It provides a detailed overview of the goods received, including information about the received items, supplier details, receiving dates, and any associated documentation.

Conclusion

Transitioning away from a paper base warehouse solution and moving into a modern WMS can be a complex process that could take over a year from listing the requirements needed until go to live. Additionally, a successful implementation will be just half the battle. Hundreds or even thousands of hours will be spent in training, tailoring, and optimization of the WMS. Ultimately, the success of the project boils down to choosing the right tool and the right partner to do the right job.

Thank you for reading this article. If you are looking to transition from a paper based system and would like to have a resource that will make the journey easier, download this WMS Functional Template.