In Warehouse Management Systems, fabricating is the process of creating products within the warehouse by transforming raw materials or components into finished goods.

Fabricating is vital for warehouse management as it allows businesses to create customized products, manage inventory effectively, and adapt to changing customer demands. Grasping the concept of fabricating is essential for enhancing warehouse operations and improving supply chain efficiency.

Key Takeaways

- Fabricating in WMS involves creating products within the warehouse.

- It transforms raw materials into finished goods.

- Fabricating enables businesses to produce customized products.

- Effective fabricating improves inventory management.

- It enhances overall supply chain efficiency.

The Definition of Fabricating in Warehouse Management

Fabricating in warehouse management refers to manufacturing or constructing items within the warehouse to meet customer requirements or support operational needs.

The fabrication process in warehouse management involves activities like cutting, shaping, and assembling materials to produce a final product. This ranges from basic tasks such as packaging and labeling to more intricate operations like metal fabrication and woodworking.

Businesses can enhance operational efficiency by incorporating fabrication capabilities in their warehouses. This reduces dependence on external suppliers and shortens lead times, providing greater control over production and allowing for quicker responses to changing demands and customer needs.

Fabricating in a warehouse can save costs by lowering transportation expenses and facilitating just-in-time production. It also offers customization and flexibility, providing a notable competitive edge.

Historical Evolution of Fabrication in Warehousing

The historical development of fabrication in warehouses is a story of continuous innovation. Initially, fabrication techniques were rudimentary, relying on manual labor and basic tools.

Over time, advancements in metal fabrication and other technologies have significantly enhanced the precision and efficiency of fabrication processes.

The introduction of computer-aided design (CAD) software and automated machinery has further revolutionized fabrication in warehouses, allowing for more complex and customized components to be produced in-house.

This evolution has not only improved the quality of fabricated parts but also reduced lead times and increased overall productivity in warehouse operations.

Key Components of the Fabrication Process in WMS

The fabrication process in Warehouse Management Systems (WMS) involves several key components that enable efficient and accurate creation of materials and products.

Two critical aspects of the fabrication process are welding and fastening, as well as adhesives and alternative joining methods.

Welding and Fastening

Welding and fastening are crucial methods in material fabrication. Welding joins metal parts through heat, while fastening uses mechanical devices to hold materials together.

Adhesives and Alternative Joining Methods

Adhesives and alternative joining methods provide additional options for fabricating materials. Adhesives are used to bond materials together, while alternative joining methods, such as riveting and bolting, offer flexibility in the fabrication process.

The combination of these techniques enables warehouses to efficiently fabricate materials and products, ensuring accuracy and quality in their operations.

Types of Fabrication Techniques Used in Warehouses

Warehouses utilize different fabrication techniques to improve efficiency and productivity. The fabricating industry employs a range of methods to customize and enhance warehouse operations.

Sheet Metal Work

Sheet metal work is a common fabrication technique used in warehouses for creating storage solutions, shelving, and equipment enclosures. It involves cutting, bending, and assembling sheet metal to meet specific requirements.

Structural steel fabrication is another critical technique used in warehouses for constructing frameworks, mezzanines, and racking systems. It involves welding, cutting, and shaping steel to create robust structures that support warehouse operations.

Both sheet metal work and structural steel fabrication contribute significantly to the flexibility and adaptability of warehouse management systems, enabling businesses to respond to changing demands and improve their overall efficiency.

Integrating Fabrication with Warehouse Management Systems

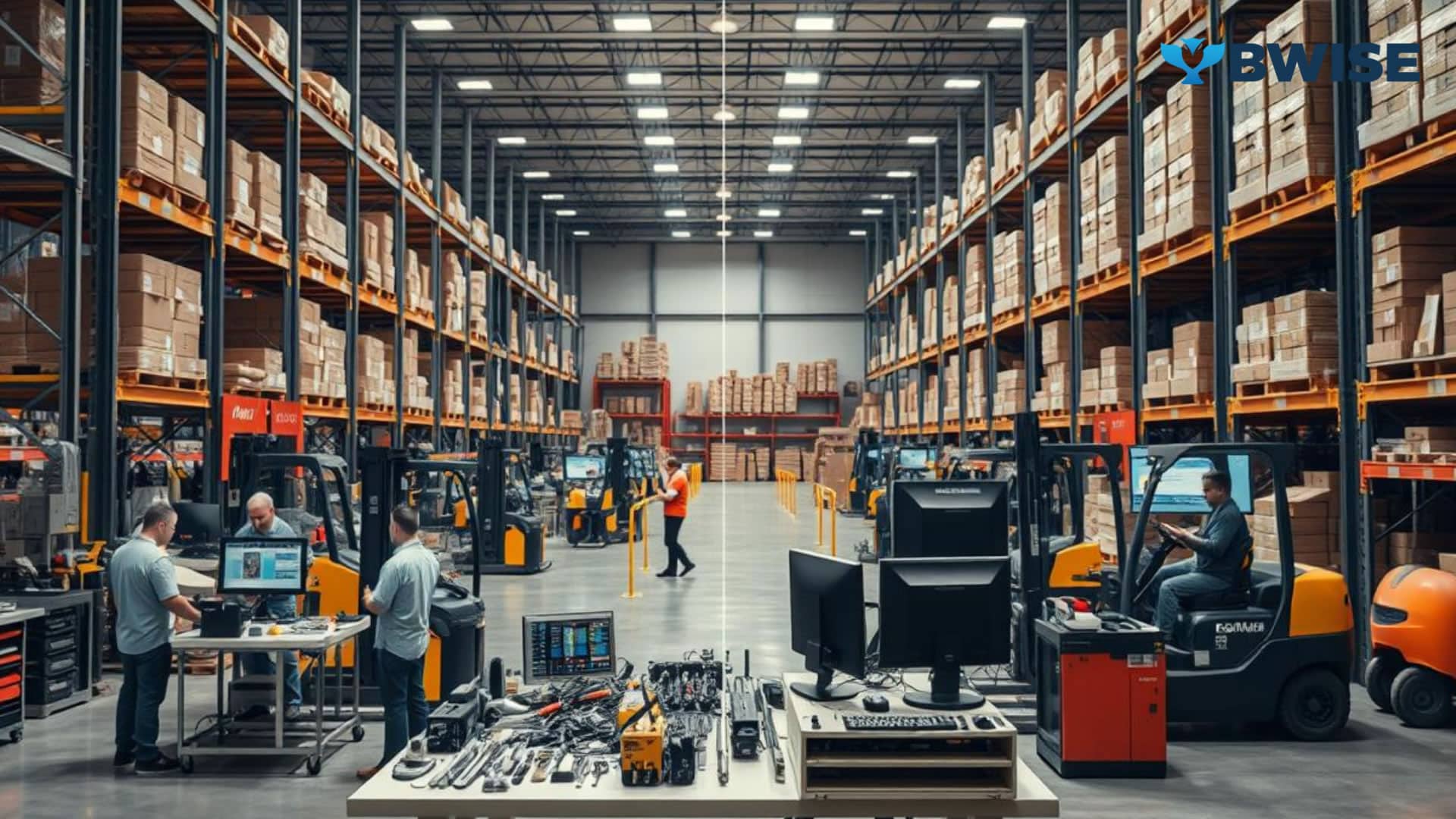

Effective integration of fabrication with Warehouse Management Systems can significantly streamline production and inventory management. By combining these two critical aspects of modern manufacturing and logistics, businesses can achieve a more cohesive and efficient operational framework.

Fabricating workshops within warehouses play a crucial role in this integration. These workshops enable the on-demand production of parts and components, reducing the need for external suppliers and minimizing lead times. The definition of fabricating in this context involves the creation of customized or standard components using various manufacturing techniques, such as cutting, bending, and welding.

When fabrication is integrated with WMS, businesses can enjoy real-time inventory tracking, automated production scheduling, and optimized resource allocation. This integration ensures that production is aligned with demand, reducing waste and improving overall efficiency.

The integration offers several benefits, including improved accuracy in forecasting and planning by connecting the fabrication process with the warehouse management system. This connection helps businesses quickly adapt to demand changes, enhance product quality, and lower costs related to inventory and production delays.

Optimizing the fabrication process within a Warehouse Management System allows companies to gain a competitive advantage by enhancing operational efficiency, shortening lead times, and providing customized products tailored to customer needs.

Benefits of In-House Fabrication Capabilities

In-house fabrication capabilities enhance warehouse operations by increasing efficiency and shortening lead times, allowing for quick responses to changing demands and production needs.

A fabricating workshop within a warehouse setting allows for better control over fabricating materials and the fabrication process. This leads to higher quality products and reduced waste.

In-house metal fabrication capabilities also enable warehouses to reduce their reliance on external suppliers, thereby decreasing costs associated with outsourcing fabrication work.

Successful in-house fabrication has led to notable gains in operational efficiency and cost savings. Establishing a fabrication workshop can boost productivity and competitiveness for warehouses.

Setting Up a Fabrication Workshop Within a Warehouse

A well-planned fabrication workshop can significantly improve warehouse operations. Setting up this type of workshop requires careful consideration of the necessary space and equipment for different fabrication techniques.

The fabricating industry uses various techniques like cutting, welding, and assembly. Understanding your warehouse operations’ specific needs will aid in selecting the right equipment and layout for the workshop.

Key considerations involve establishing safety protocols, training staff in fabrication techniques, and integrating the workshop with current warehouse management systems.

By doing so, warehouses can enhance their in-house fabrication capabilities, leading to improved efficiency and reduced lead times for customized solutions.

Conclusion: The Future of Fabrication in Warehouse Management

By incorporating fabrication into warehouse management systems, businesses can streamline their processes, reduce lead times, and improve product quality. The future of fabrication in warehouse management looks promising, with advancements in technology and automation expected to further enhance fabrication capabilities.

Incorporating fabrication into warehouse management systems allows businesses to streamline processes, reduce lead times, and enhance product quality. Future advancements in technology and automation are anticipated to improve fabrication capabilities further.

As warehouses evolve, the significance of fabricating in warehouse management is increasing. Understanding fabrication allows businesses to stay competitive and leverage its advantages.